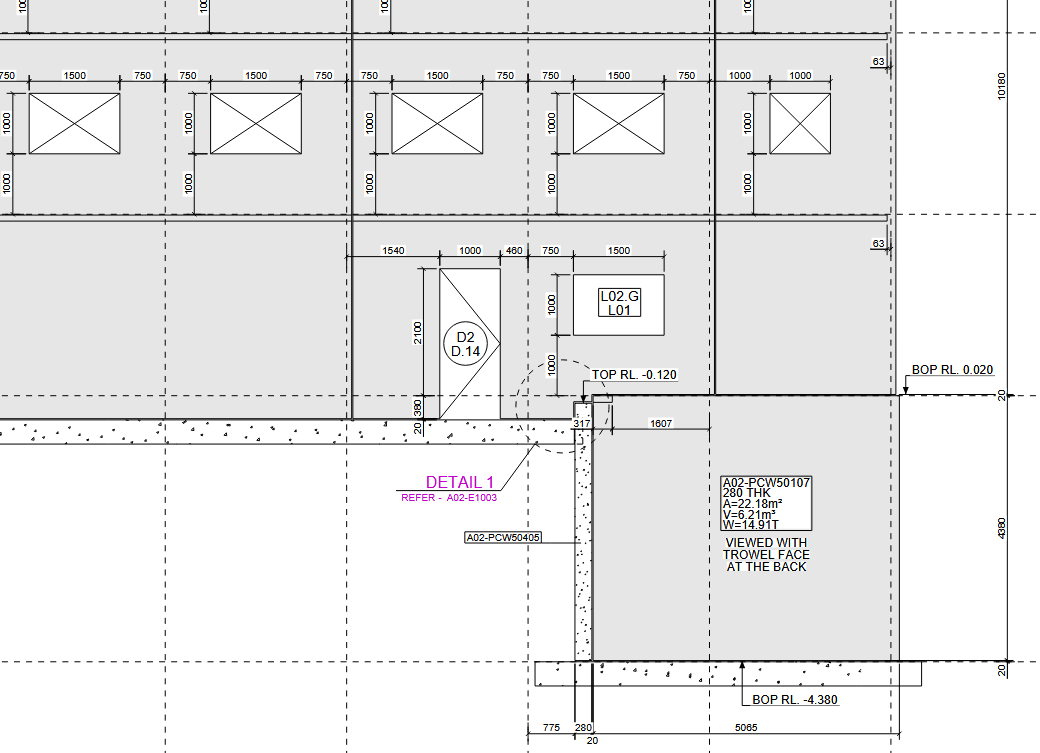

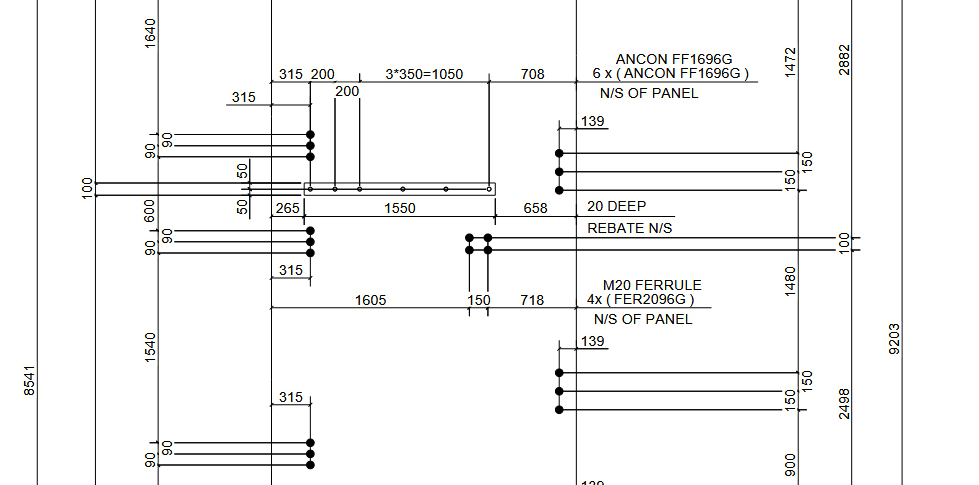

PRECAST CONCRETE DRAWING

The team at Steelcad Drafting recognise the need to provide a quality product to the Precast Concrete Industry.

Each of our contracts are allocated a Project Manager to check and oversee the modelling and detail drafting for the client. Our Project Manager will also provide you with weekly status reports to keep you up to date on any issues concerning your work. This also means you have a single point of contact for all correspondence on the job.

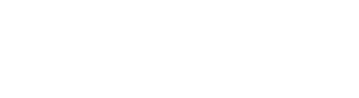

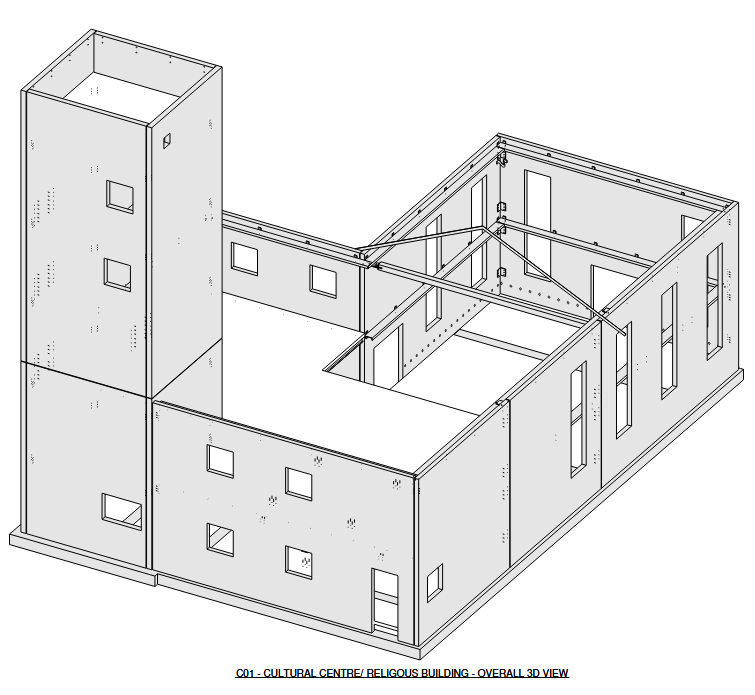

Shop Detail Drawing deliverables are:

- Footing Dowel Drilling– Details & Layouts

- General Arrangement Drawings – Marking Plans, Elevations.

- Assembly drawings –

- One Drawing Per Panel

- Any Steelwork in our scope

- Fitting Sheets – Single Part Drawings of any Steel Parts in our scope

To help streamline the fabrication process, Steelcad can provide CAM data for mass processing of shaft members and plates.

This data, coupled with report information for part quantification, can be passed on to the Steel Fabricator, Merchant, or Roll Former for processing.

The Precast Panels do not require any CAM data.

Electronic deliverables are:

- PDF Drawing Files

- DSTV file – NC or CAM data of shaft members

- DXF file – 2D to scale plate shape file

Additional to the delivery of Shop Detail Drawings, Steelcad offers a set of standard reports to accompany the drawings.

The report information can be used to track material sizes and quantity. Information such as Tonnage, Paint system and Marking Plan reference can all be retrieved from the reports.

Report deliverables are:

- Transmittal – List of drawings on issue

- Assembly

- Mark

- Material

- Field Bolt List

- Bolt Summary

Custom reports can be developed to suit your requirements so please don’t hesitate to ask.