Structural Steel Shop Detailing

The team at Steelcad Drafting recognise the need to provide a quality product to the Steel Fabrication Industry.

Our Project Managers have years of experience in steel construction, from design and detailing through to fabrication, surface treatment, transport & erection. All our drawing office modelers and detailers receive in-house training and professional development to keep them up to date with latest processes and techniques.

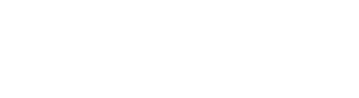

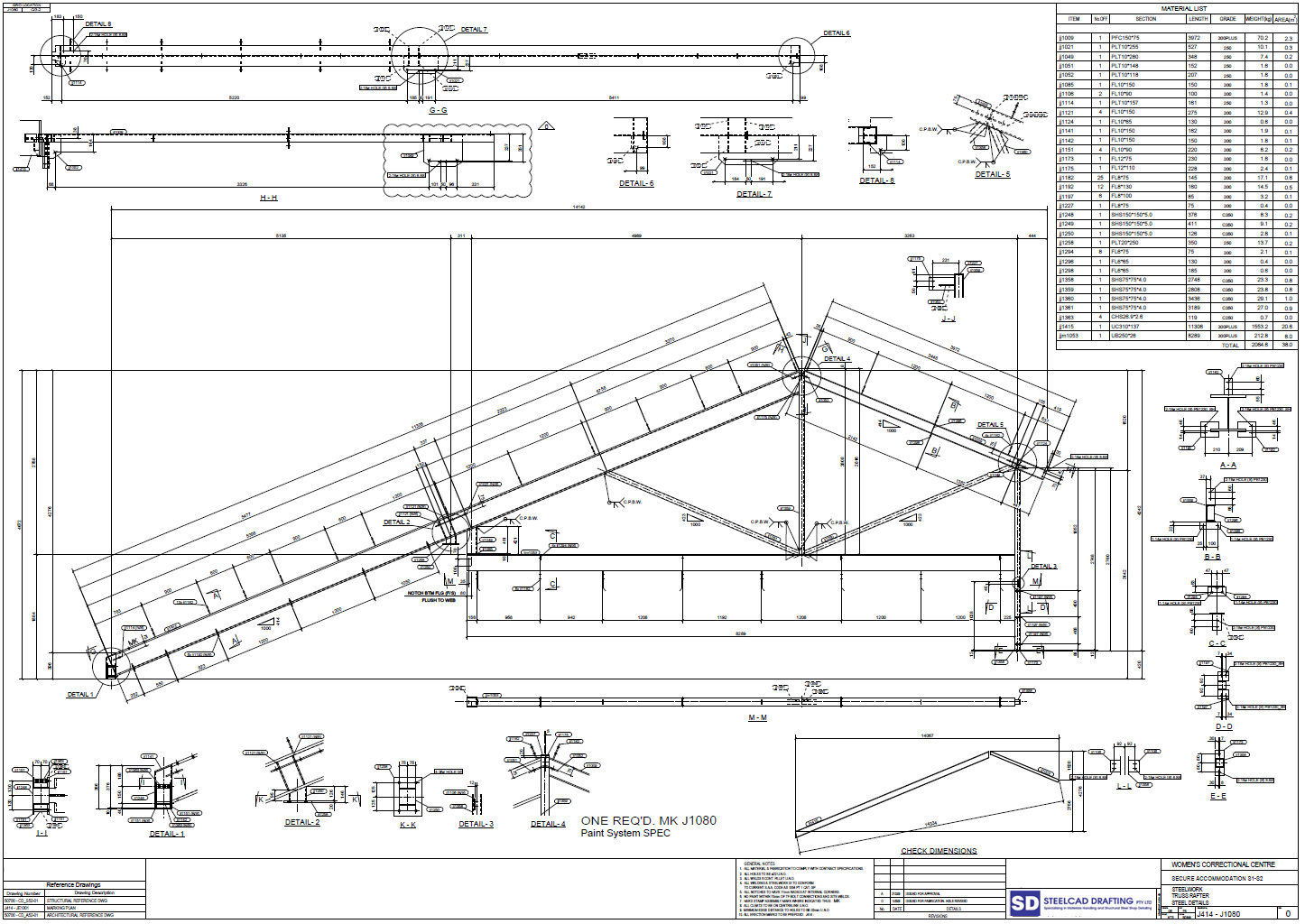

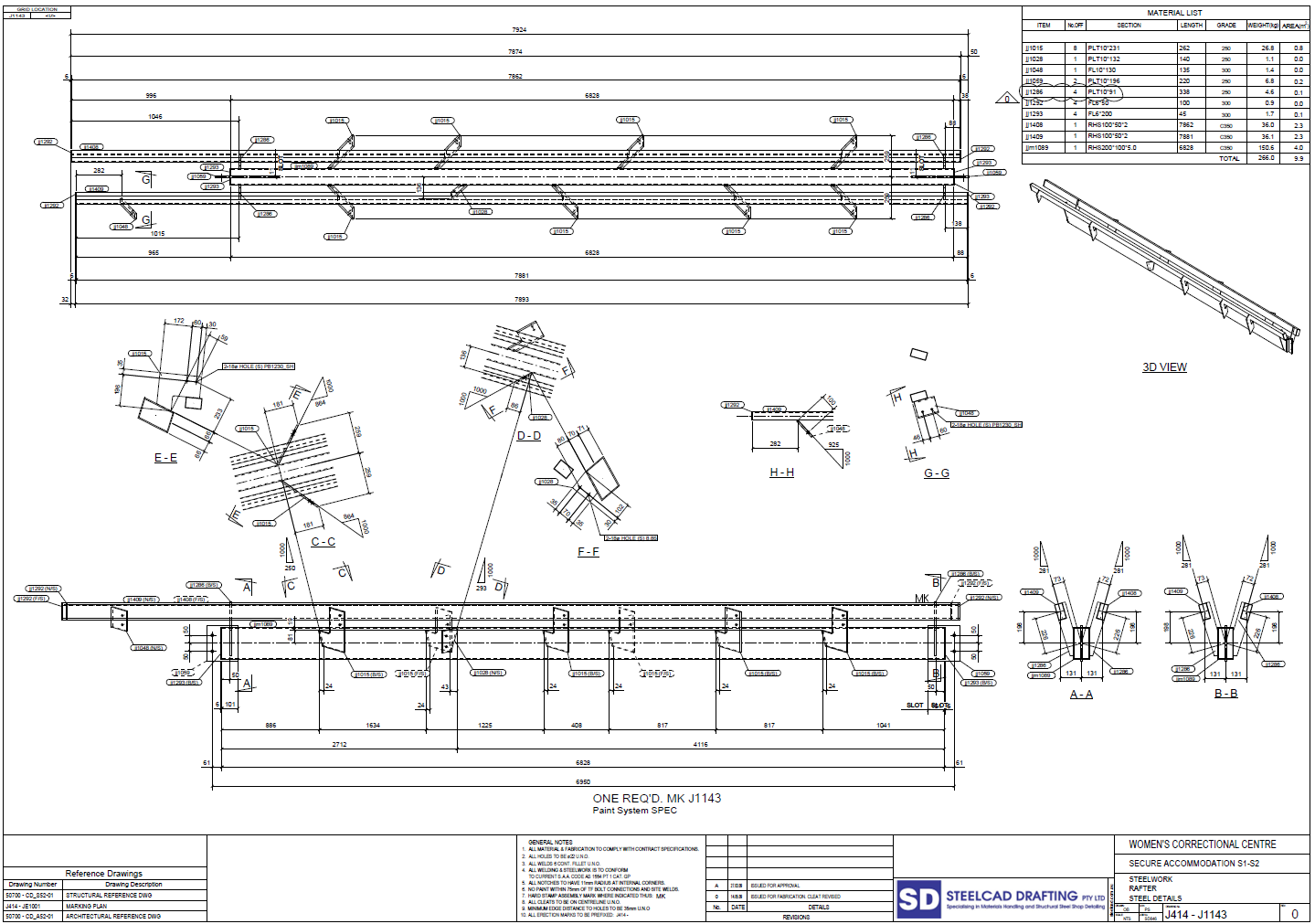

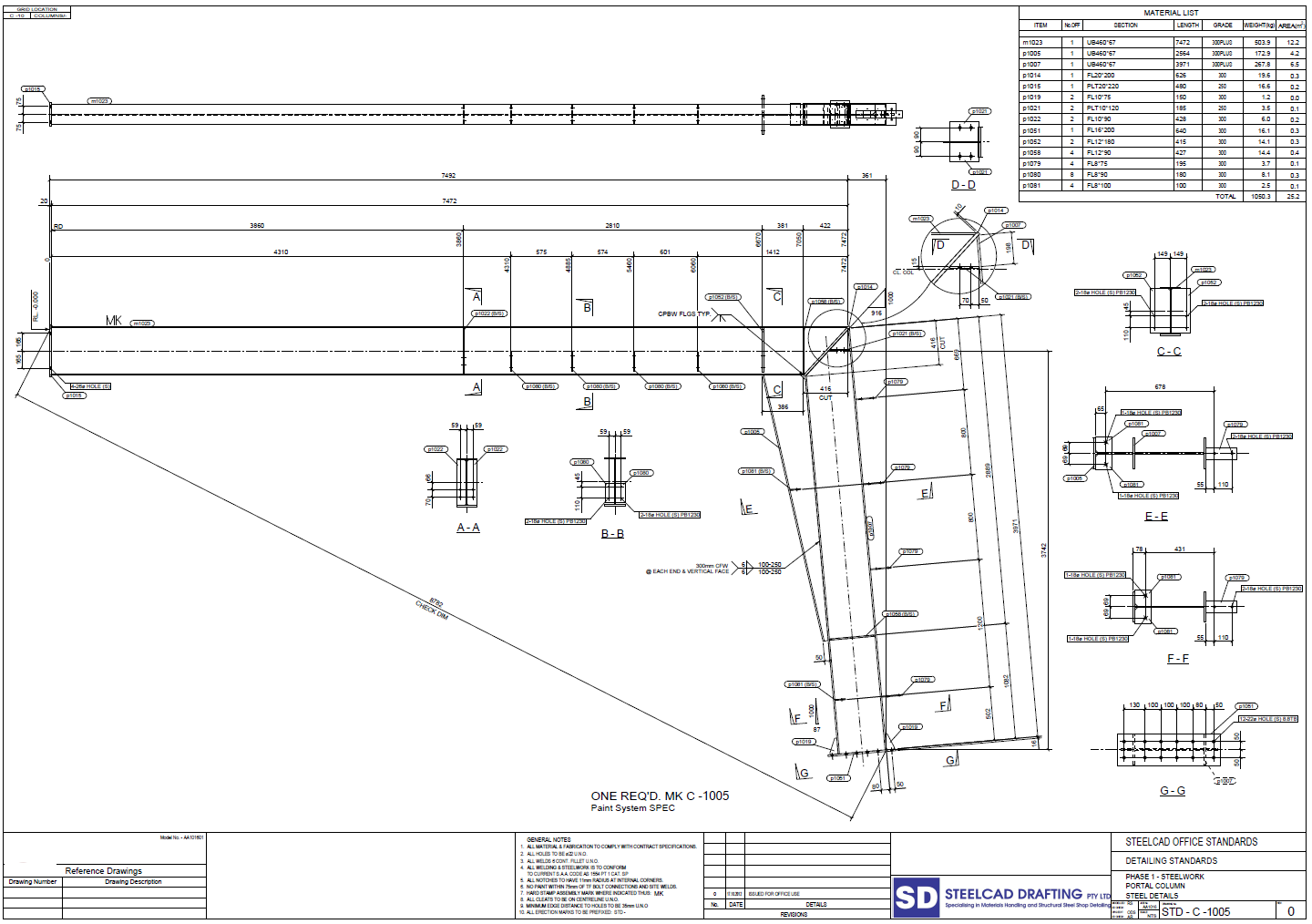

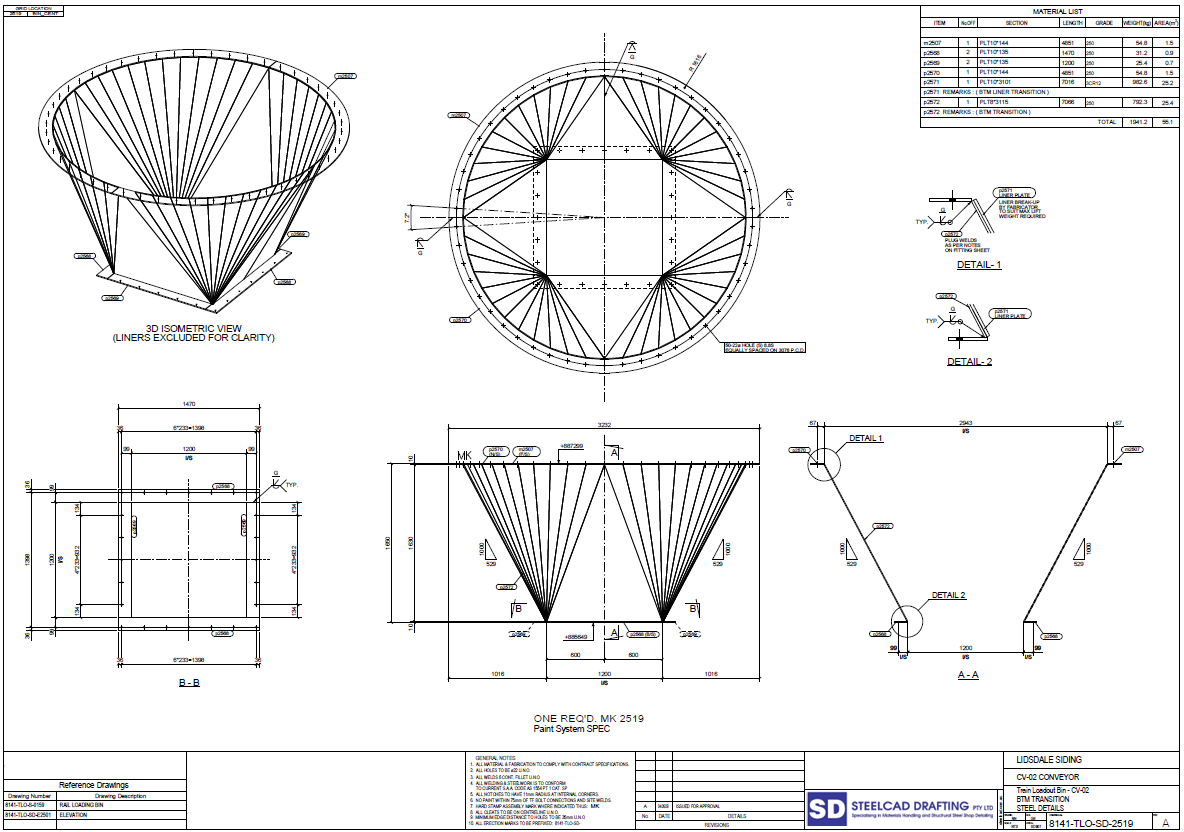

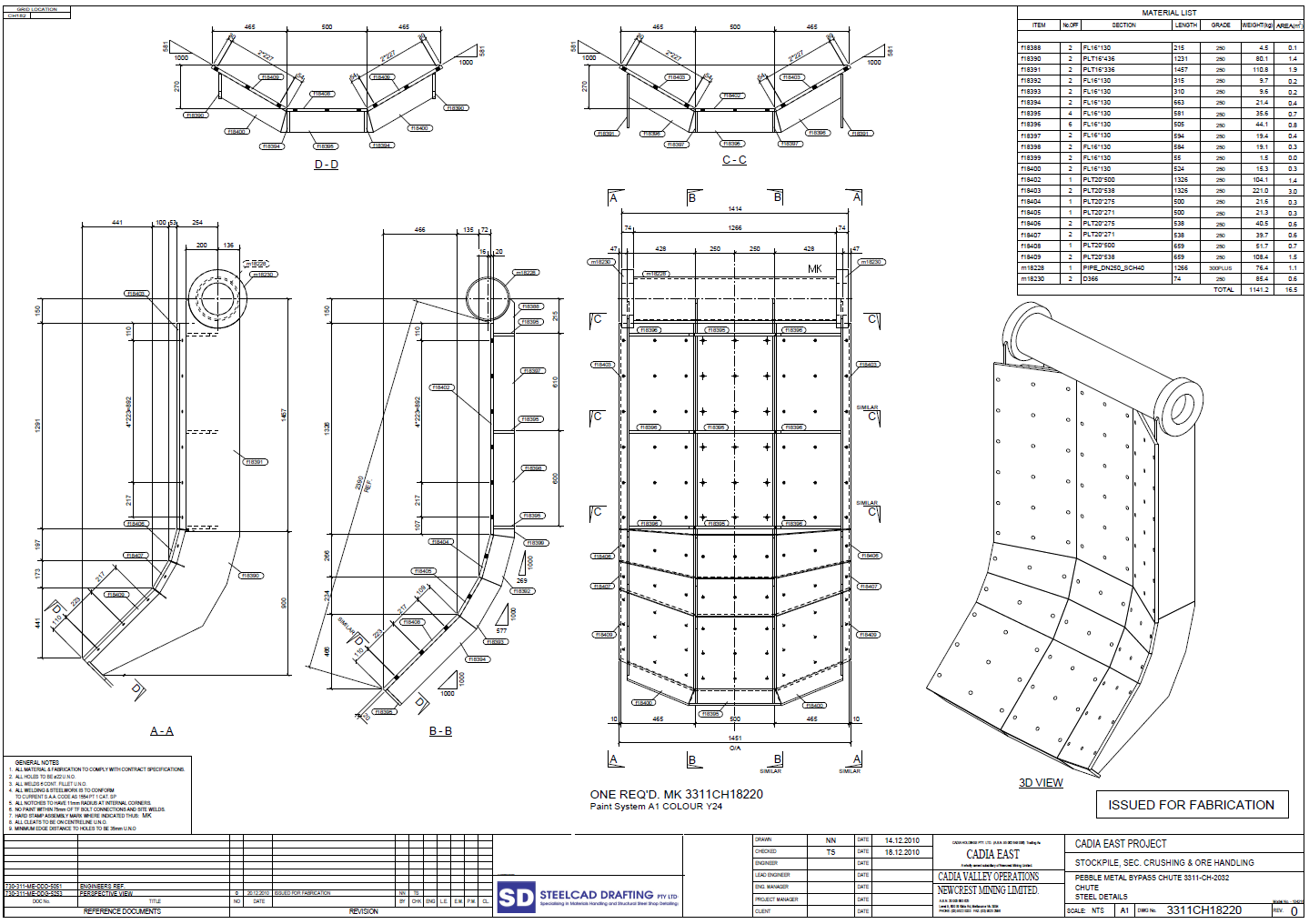

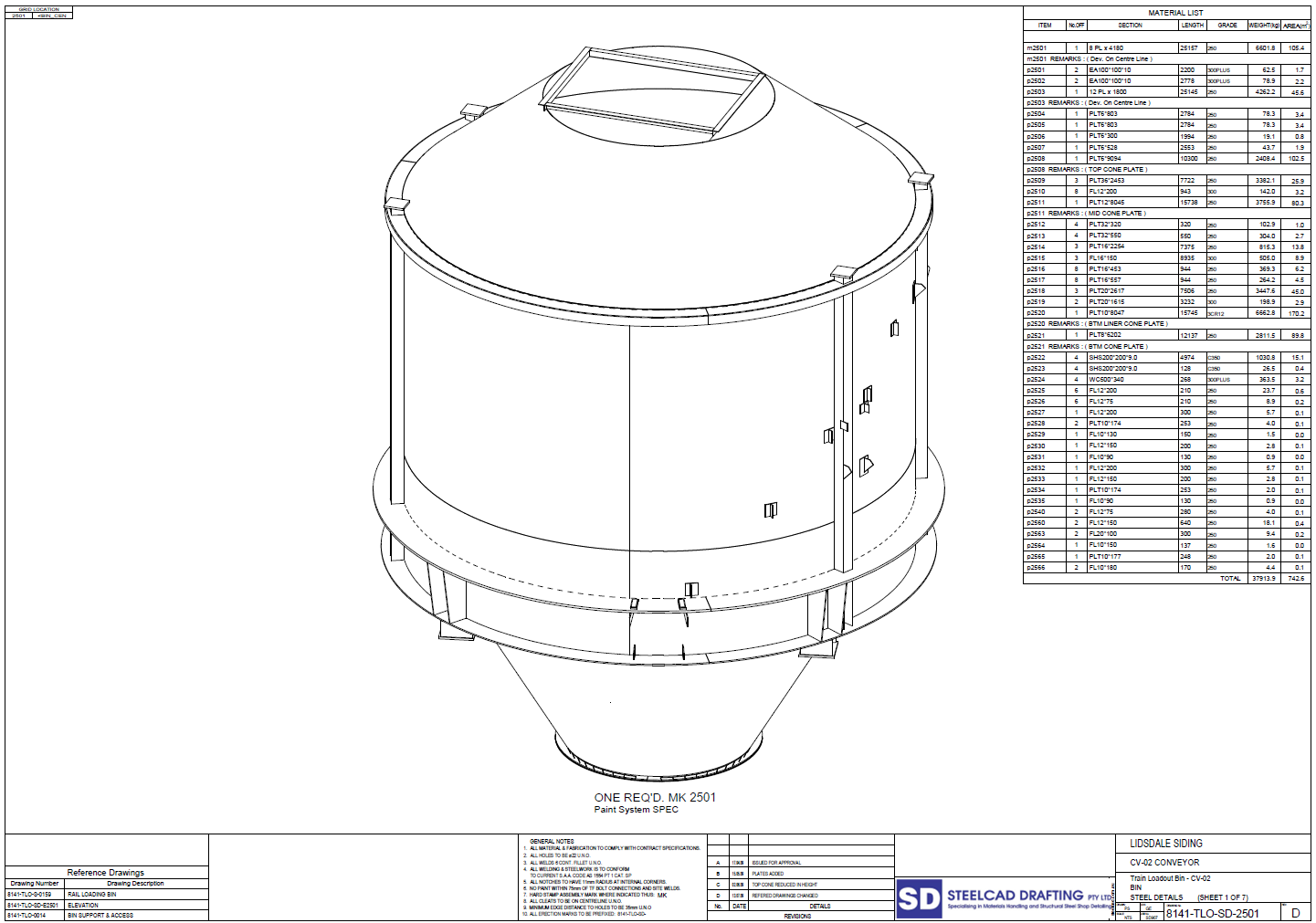

Shop Detail Drawing deliverables are:

- Hold Down Bolts – Details & Layouts

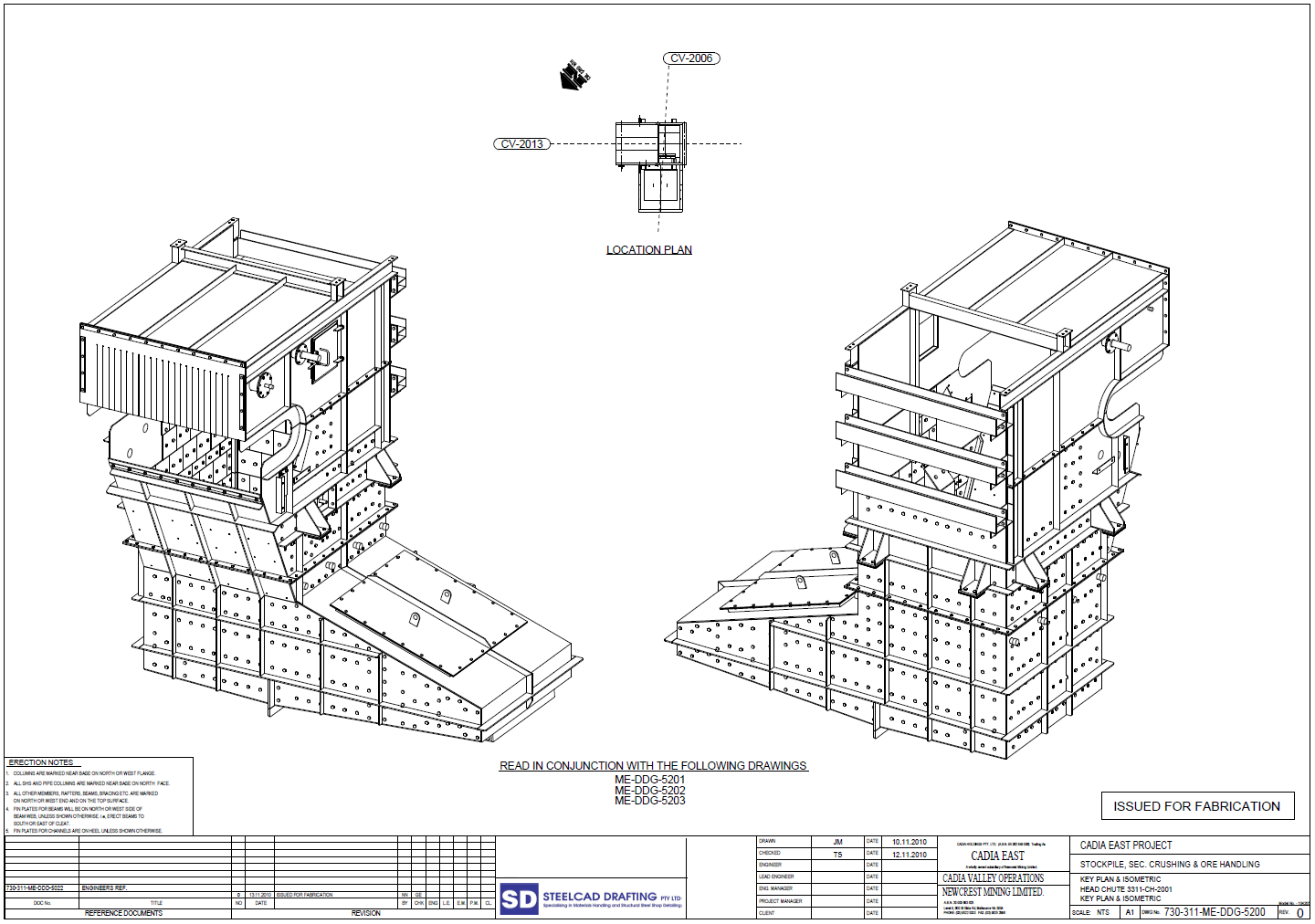

- General Arrangement Drawings – Marking Plans, Elevations, Handrail & Grating Layouts

- Assembly drawings – Structural & Mechanical

- Fitting Sheets – Single Part Drawings

- Full Size Wrap Templates – for complex pipe cuts

To help streamline the fabrication process, Steelcad can provide CAM data for mass processing of shaft members and plates.

This data, coupled with report information for part quantification, can be passed on to the Steel Fabricator, Merchant, or Roll Former for processing.

Electronic deliverables are:

- PDF Drawing Files

- DSTV file – NC or CAM data of shaft members

- DXF file – 2D to scale plate shape file

- Floor Grating Plans to scale in DWG format – for Grating Manufacture

Additional to the delivery of Shop Detail Drawings, Steelcad offers a set of standard reports to accompany the drawings.

The report information can be used to track material sizes and quantity. Information such as Tonnage, Paint system and Marking Plan reference can all be retrieved from the reports.

Report deliverables are:

- Transmittal – List of drawings on issue

- Assembly

- Mark

- Material

- Field Bolt List

- Bolt Summary

An Advanced Bill of Material (ABM) is also available by pre-arrangement. These can be issued at any time after the 3D structural model is complete and checked. They can be used for pre-ordering of materials to avoid shortages during critical path construction activities.

Custom reports can be developed to suit your requirements so please don’t hesitate to ask.